Polymer–

Wood–

Stir Welding

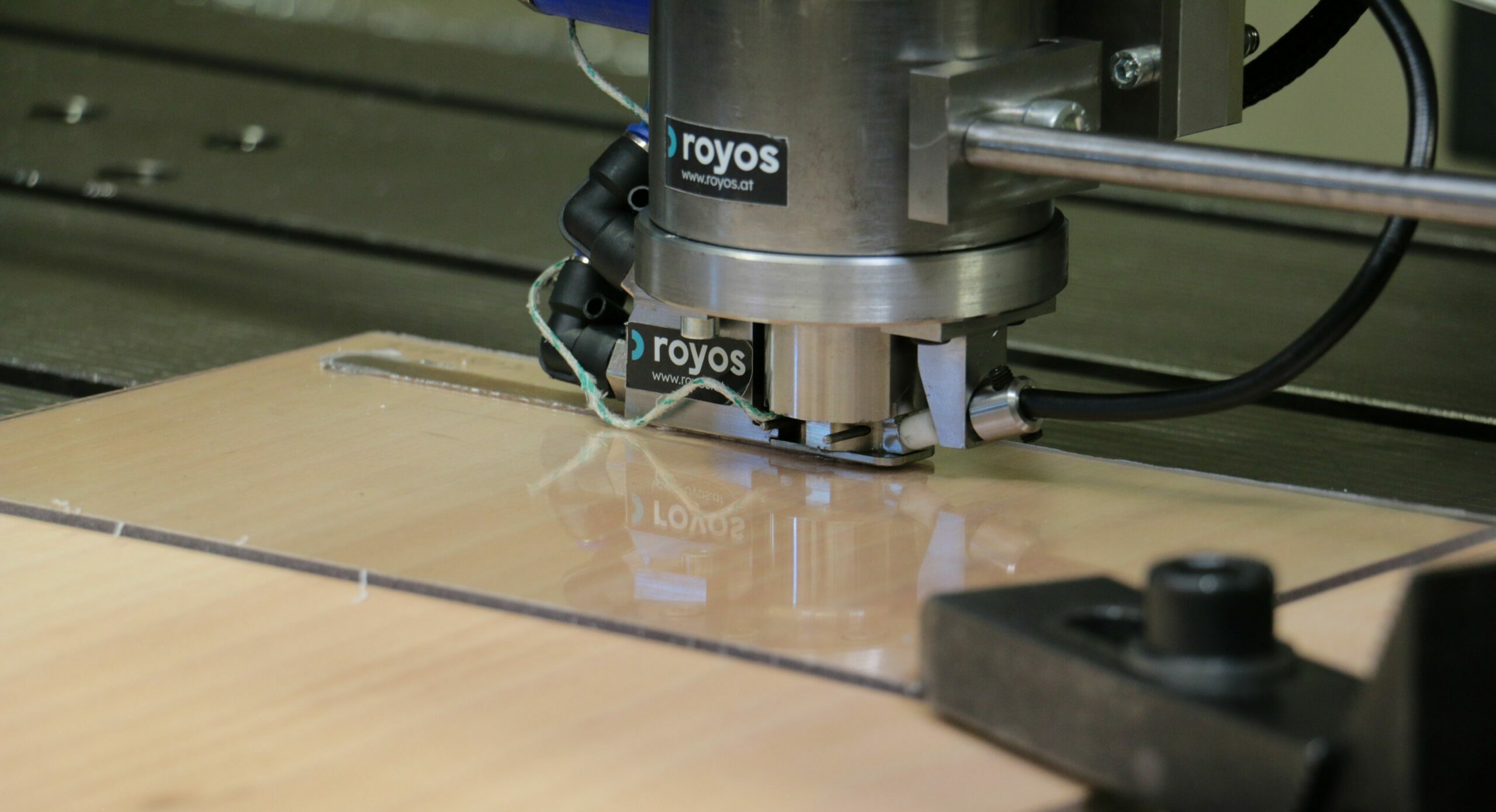

Our revolutionary technology welds wood and polymer in a single step – permanently, efficiently, and completely without adhesives.

Our innovative process sets new standards in joining technology: for the first time, wood and polymer can be permanently and securely welded together in a single step – completely without adhesives or additional fasteners.

This groundbreaking technology opens up entirely new possibilities in design and manufacturing. It combines maximum strength with a streamlined, efficient production process and offers significant cost advantages. Especially in lightweight construction, furniture manufacturing, and sustainable materials, it creates entirely new design and application opportunities.

Embrace the future of material joining – for durable, sustainable, and innovative products.

Perfect joining

without adhesives or screws

Fast, environmentally friendly

and efficient processes

High strength and

aesthetics combined

The Technology

Strong polymer-wood joints without pretreatment

Our technology enables the direct joining of textured or natural wood with technical polymers – form-fit, media-tight, and process-reliable.

royos connects nature and technology – permanently, efficiently, and with maximum design freedom.

When polymer and wood simply fit together

Our solution saves time, weight, and cost: instead of complex assembly, we join polymer directly to wood – permanently strong, without screws or adhesives.

royos harmonizes high-performance polymers and natural materials – for smart, sustainable products.

Function meets design

Wide range of possible combinations

The PSW process turns the pane into a load-bearing element. Wood-plastic combinations in lightweight construction or for extravagant design

By using biogenic thermoplastics, the component can be biodegraded at the end.