Polymer–

Polymer–

Stir Welding

High-Strength Welds for Technical Polymers

Efficient welding of high-performance polymers

Our technology permanently welds even challenging polymers with media resistance and form-fit – all without adhesives or solvent-based processes.

- More economical than adhesive bonding, more sustainable than multi-material adhesives

- Durable and recycling-friendly – no foreign materials in the component

- Wide material range: PP, PA6, PBT, TPE, and many more

We unlock new applications in lightweight construction, medical technology, and mobility – using a reliable, scalable process.

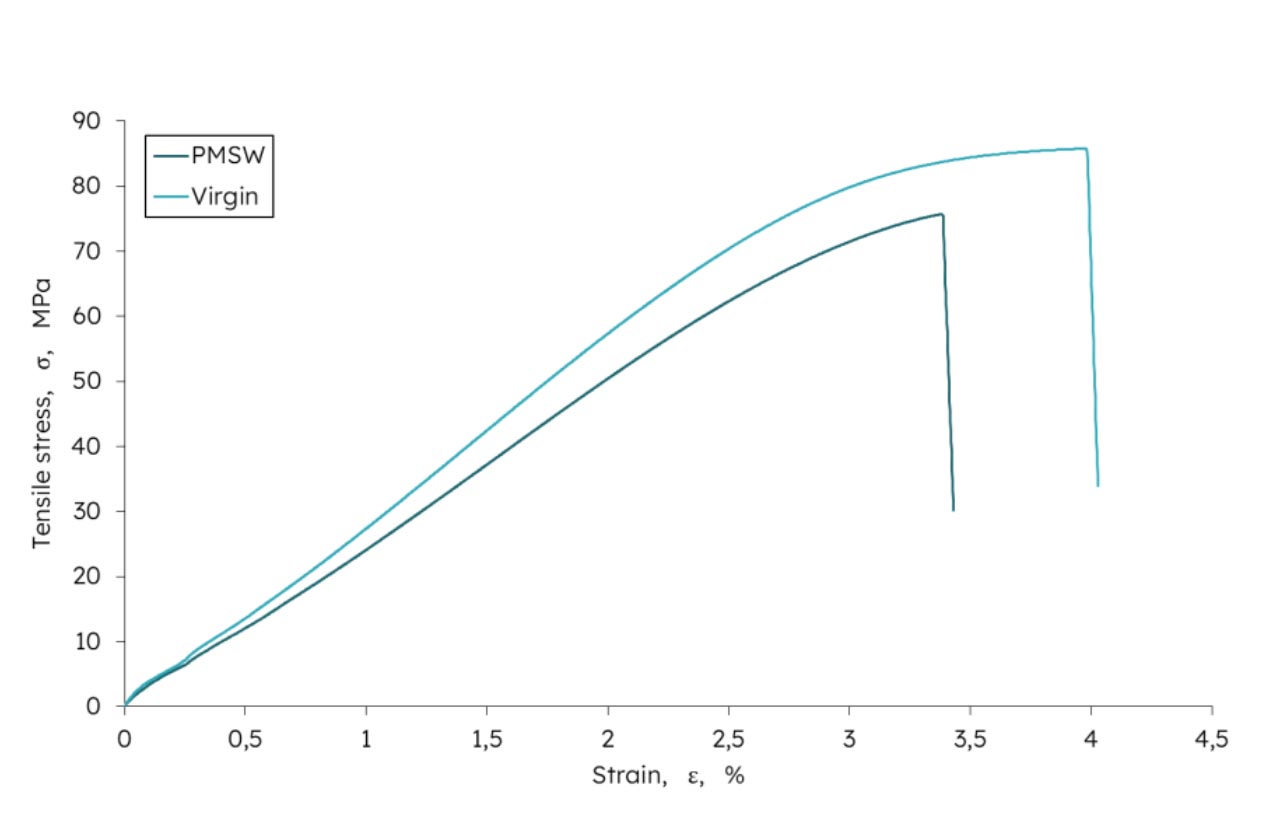

High-strength joining

of polymers

Also joins fiber-reinforced

polymers

Combines different materials

Typical Applications

Polymer-to-polymer welds taken to a new level

Our technology enables reliable welding of various polymers – including glass fiber-reinforced and soft-hard combinations – with high strength and low thermal stress.

royos replaces adhesives and screws with true material fusion – for durable and sealed polymer components.

Efficiently joining polymer parts

Our polymer-to-polymer connections save assembly time, reduce manufacturing costs, and enhance product quality – all without adhesives or sealants.

royos joins polymers smarter – for more efficient products and leaner processes.

Your Advantage