Polymer-

Metal-

Stir Welding

Innovation: Patented PSW technology for polymer-metal welding

The future of hybrid materials.

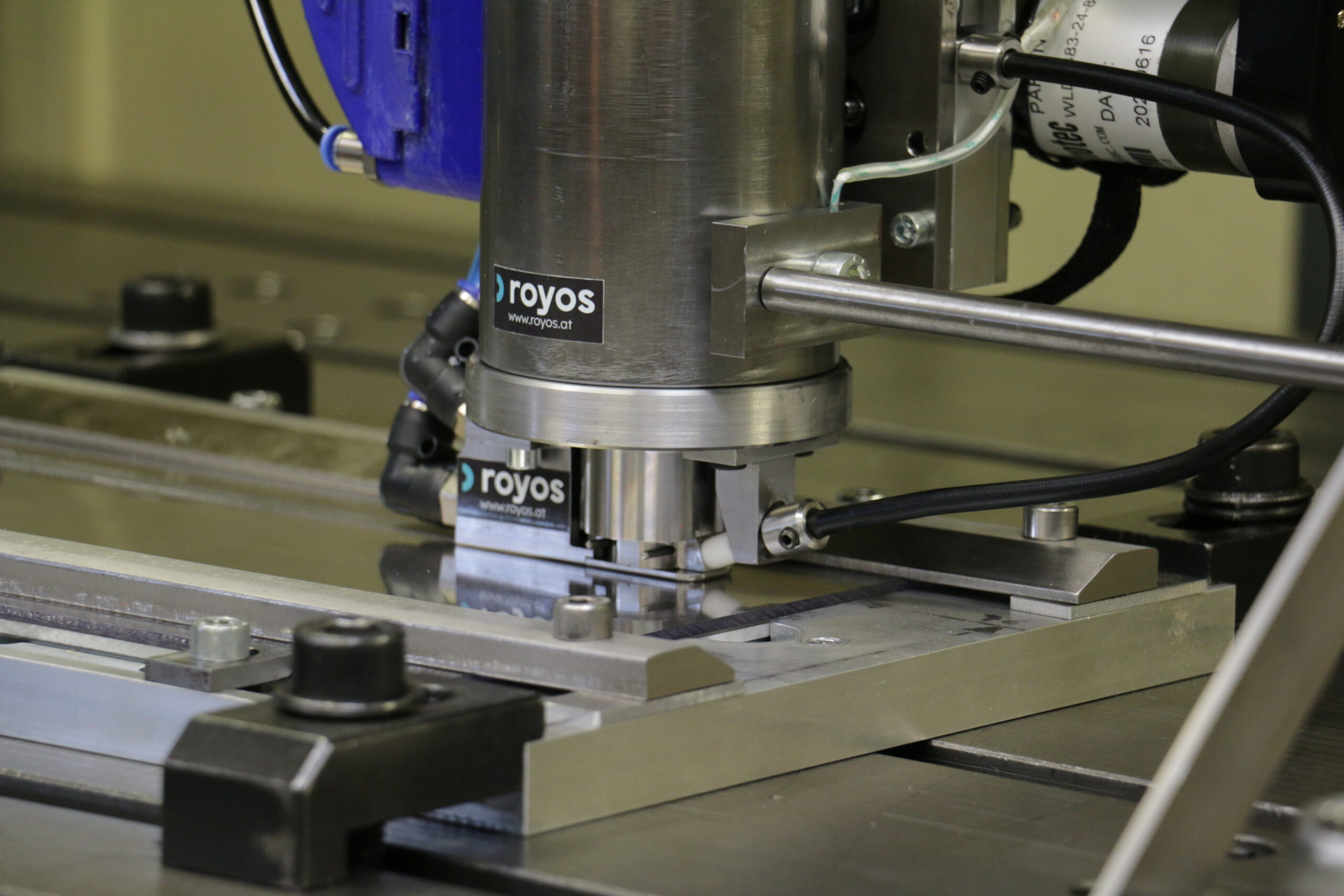

With our patented Polymer Stir Welding tool, you fuse polymers and metals in a single, fully automated step – producing pore-free, high-strength assemblies without the need for screws, adhesives, or seals. This smart material fusion reduces part costs, saves weight, and significantly shortens your process chain. Operating at low temperatures and with minimal energy input, the process is highly resource-efficient and ideal for circular product design. Whether it’s aircraft structures, battery housings, or precision components – our plug-and-play tool scales effortlessly from the first prototype to high-volume production, making royos a technology leader in the growing market for hybrid lightweight solutions.

Lightweight design and material variety

Cost efficiency and

sustainability

Versatile applications

We join the future.

The Technology

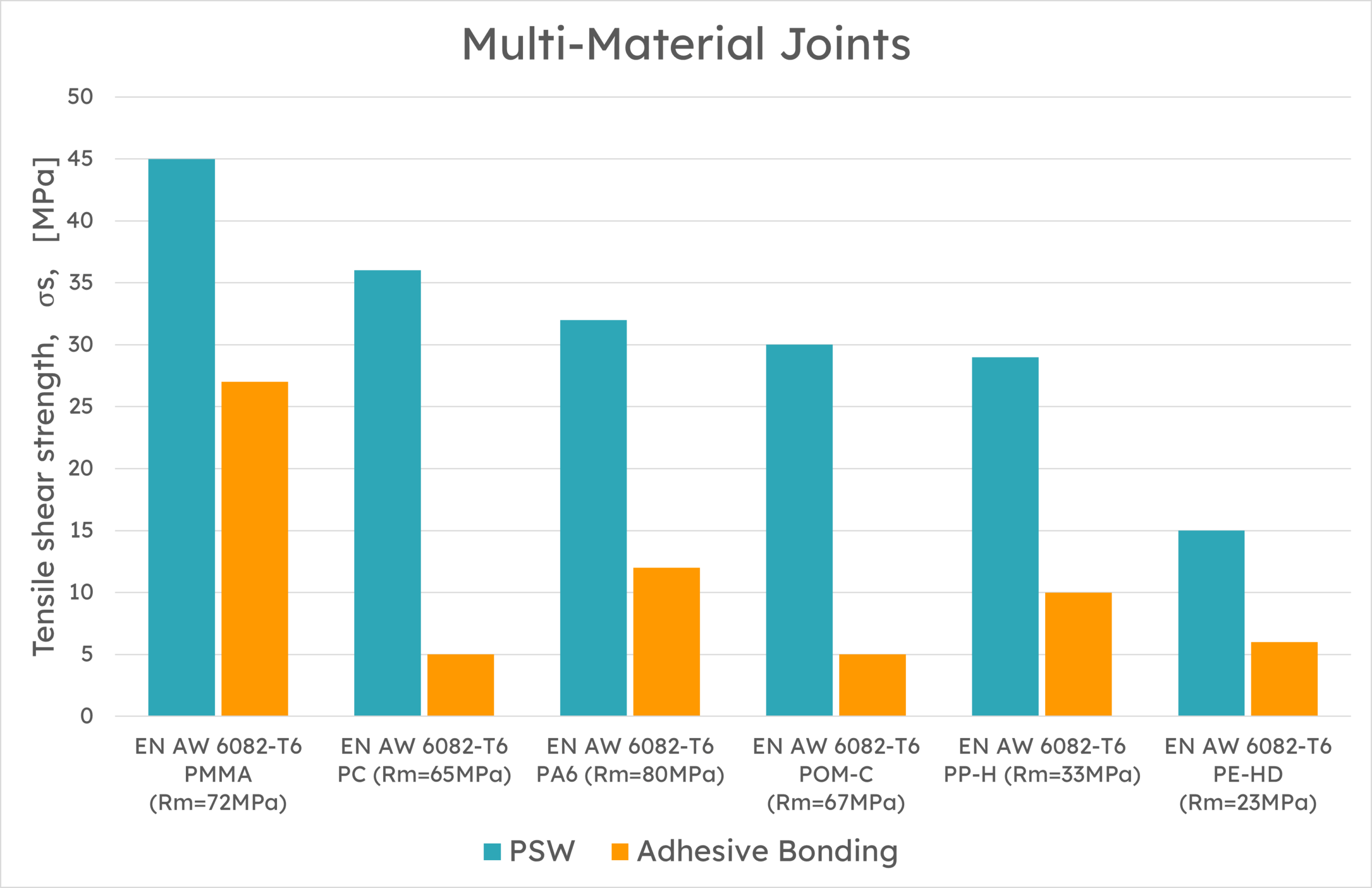

PSW enables high-strength hybrid joints between metal and polymer, even with demanding fiber-reinforced materials like PA6 GF30. The tool stirs the interface layer of both materials directly – without any pretreatment, adhesives, or screws.

PSW enables a paradigm shift in component design: heavy aluminum housings are replaced by lightweight polymer structures; aluminum cold plates are welded in only at critical heat dissipation Points.

In short: PSW makes your components lighter, your production cleaner, and your cost calculations leaner.

Your advantages