Consulting

We offer consulting, development, and FSW training.

To us, consulting is a form of craftsmanship – bringing together knowledge and experience to support you where it truly matters.

We’re at your side when it comes to selecting suitable materials, designing weld seams optimized for FSW, and understanding the capabilities and limits of the process.

Technical expertise and

specialized know‑how

Objective analysis and

problem solving

Resource efficiency and

flexibility

Consulting

Use our knowledge to your advantage

Over the years, we’ve gained extensive experience in designing and optimizing FSW-compatible geometries. Now, we’re ready to share this expertise to help you prepare your components for efficient series production. Our focus lies on overall feasibility – from the manufacturability of cast parts to the optimization of joint zones specifically for the FSW process.

Integrating our FSW expertise early in the development process has proven to save valuable time and prevent high costs later in production. Smart joint design enables significantly higher welding speeds down the line – gaining precious seconds in cycle time. We also evaluate tool accessibility and support surface requirements to minimize the risk of additional costs later on.

Leading OEMs and Tier 1 suppliers already rely on our know-how to develop outstanding and cost-efficient friction stir welded components!

Design

FAQ: Commonly used

FSW joint geometries

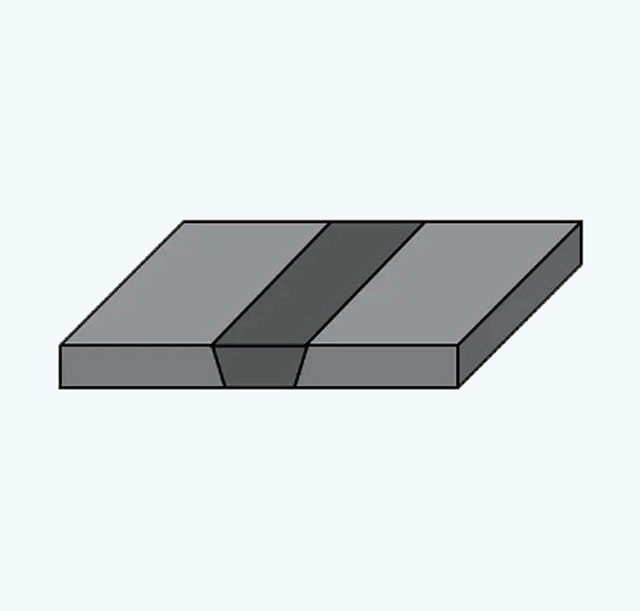

01

Butt Joint

Application: Sheets, similar and dissimilar joints, tailor welded blanks

Advantage: strong joint, no crevice corrosion

Disadvantage: mechanical processing is recommended to minimize the gap. Due to tolerances (gap/height differences), increased burr formation may occur.

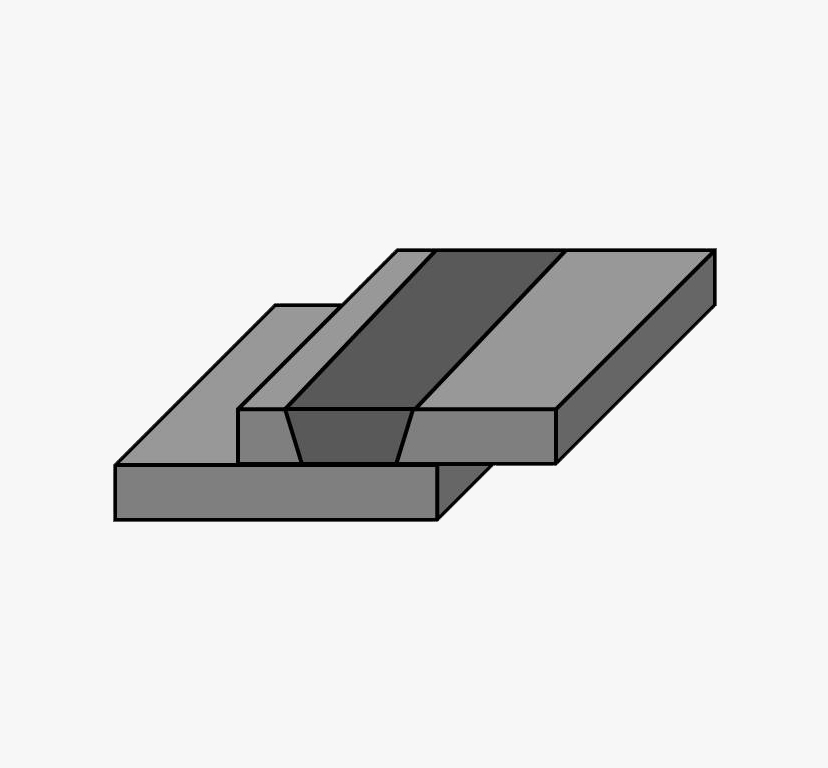

Overlap Joint

Application: Sheet metal, sheet components, and aluminum castings

Advantage: Minimal burr formation, large tolerances possible, no seam preparation required

Disadvantage: Crevice corrosion must be avoided

Overlap joint for aluminum casting

Application: Aluminum casting and sheet metal

Advantage: less burr, large tolerances possible, no seam preparation required

Disadvantage: crevice corrosion must be avoided

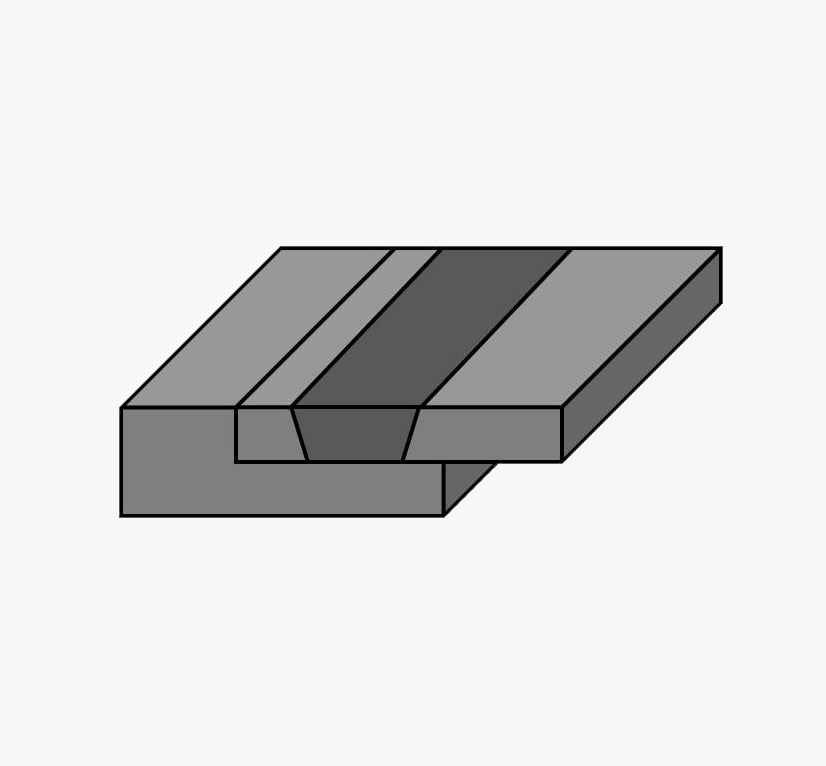

Half-Lap-Joint

Application: Aluminum casting and sheet metal

Advantage: no external crevice corrosion

Disadvantage: mechanical seam preparation recommended; burr formation depends on tolerances (gap/height differences); crevice corrosion on the inside must be avoided

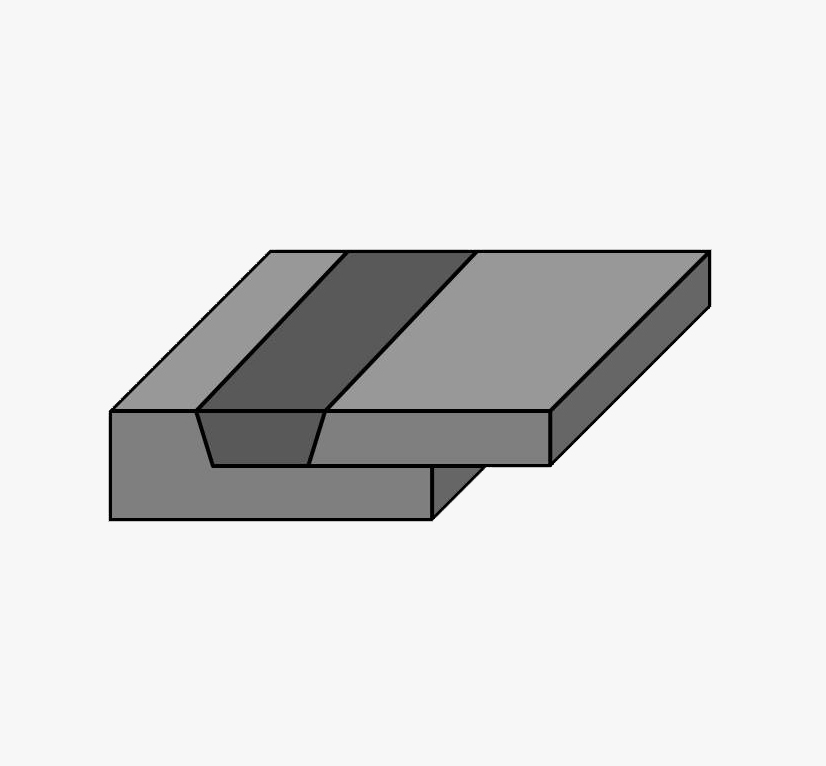

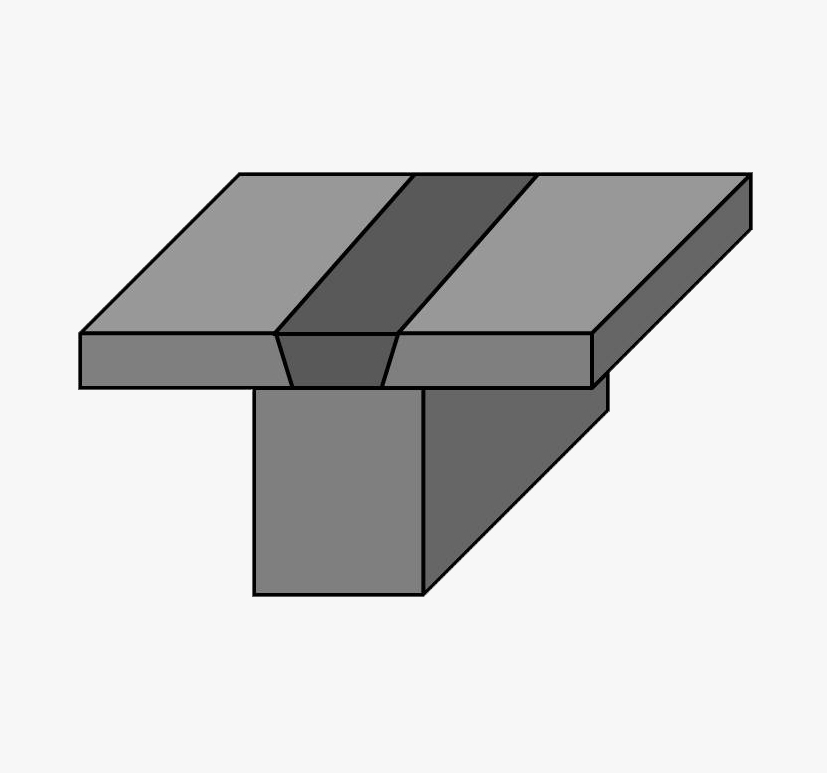

T-Joint

Application: Aluminum casting (e.g., sheet metal cover on ribs of a cast housing)

Advantage: less burr, large tolerances possible, no seam preparation required

Disadvantage: crevice corrosion on the inside must be avoided