Electronics & White Goods

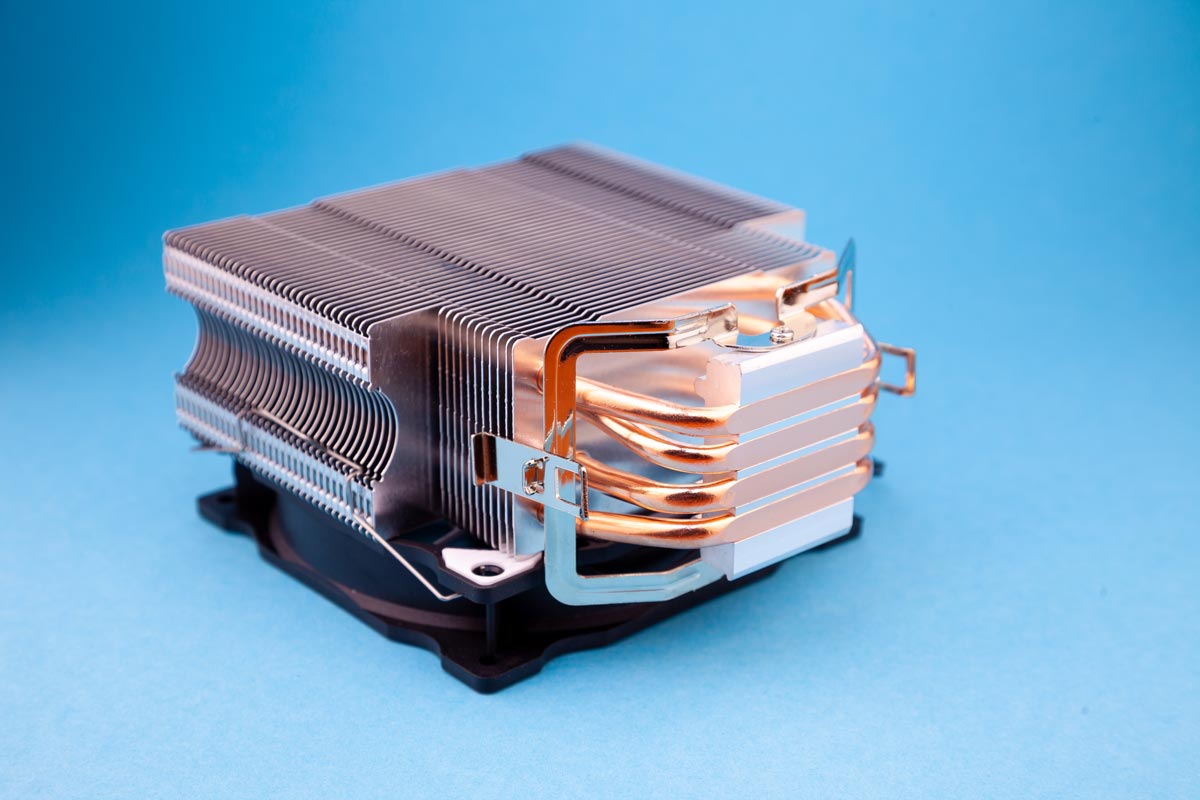

Heat Sinks & Thermal Interfaces

01

High-efficiency cooling structures for electronic components.

Protection for batteries, sensors, and smart devices.

Sealed electronic housings

02

Frames & hinges in devices

03

Polymer–metal hybrids for durable home appliances.