Automotive

Lightweight Design & Structure

Targeted use of polymers where metal would only add weight.

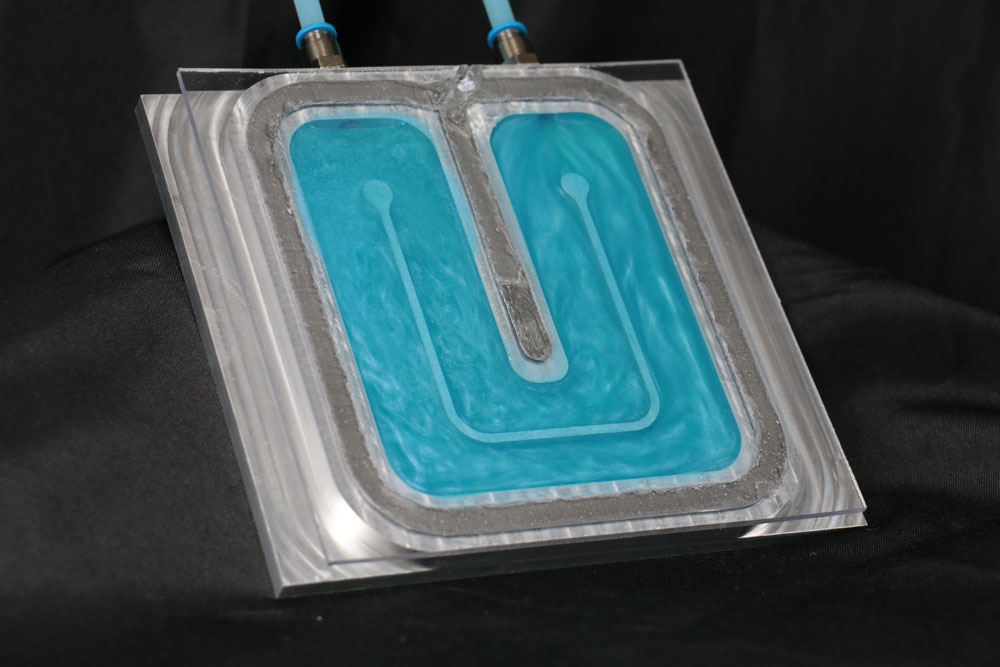

Cooling components with integrated sealing and fluid routing.

E-Powertrain & Thermal Management

Interior & Exterior Module

Invisible, tactilely flawless joints for design components.

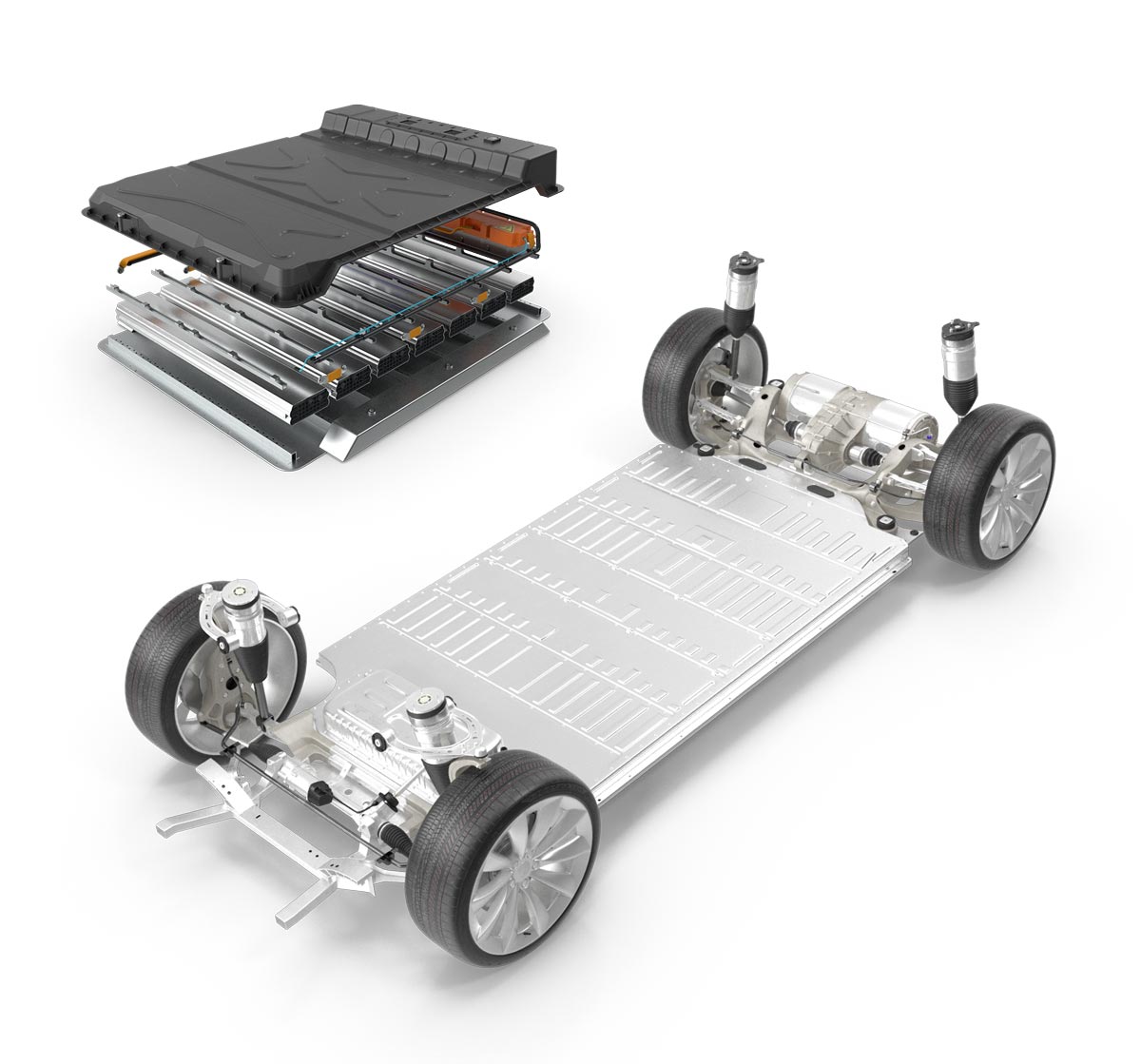

Future battery trays will be manufactured as hybrid joints of metal and polymer – enabling more affordable, lighter, and more sustainable mobility.

Expert Talk

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.